Millions of tonnes of plastic waste worldwide in our oceans, thousands of potentially dangerous shipwrecks containing heavy oil, munitions and other toxic waste; car tires, ghost nets and much more. To be able to work on these threats on a larger scale than before, we need a strong tool – a working ship with which we can effectively work on large areas with many volunteers.

A ship that optimally supports all our activities and also our principles, especially environmental and marine conservation, must meet many different criteria. We have decided to orientate on traditional cargo sailing ships. They have been used for centuries to transport goods and passengers alike across the globe. Although they are well proven and have timelessly beautiful lines, they do not easily meet today’s requirements in terms of safety, comfort and environmental protection.

Size

The minimum size for the planned missions is around 30m hull length. These are ships like Colin Archer’s Leon, for example. The upper limit is in the region of 50m. A good example of a medium-sized ship is the Georg Stage with a hull length of approx. 41m.

The Léon (1880)

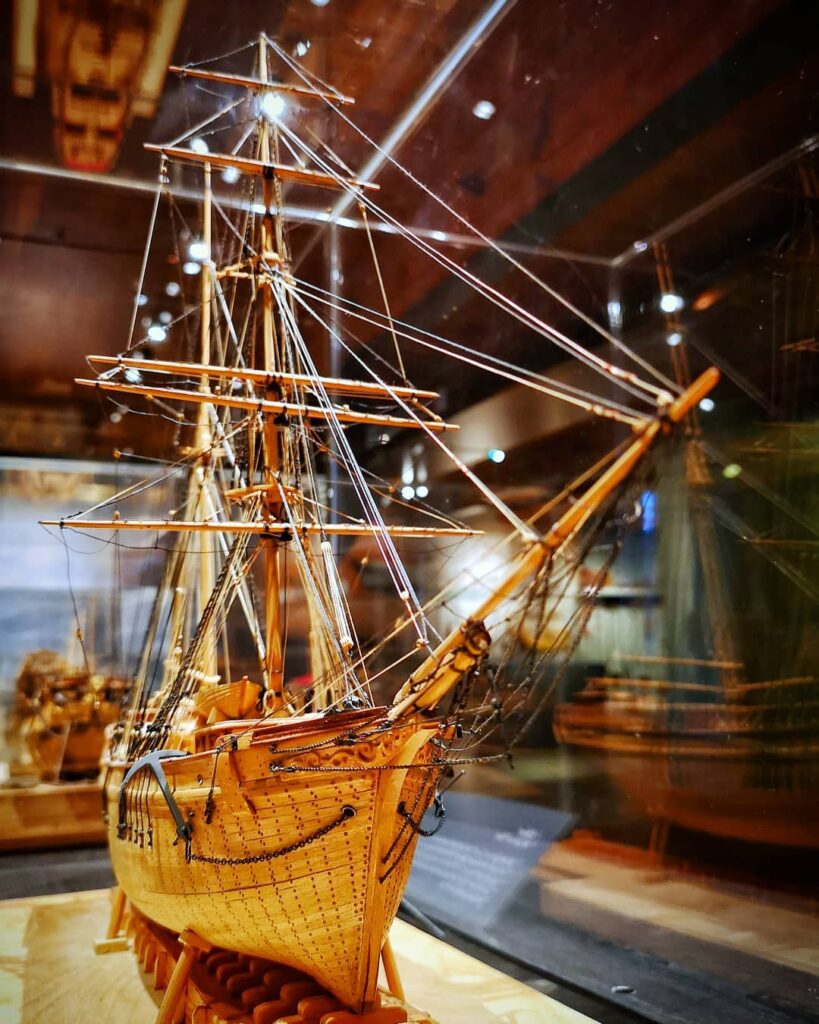

Colin Archer (1832-1921) is known to a wide audience primarily for his legendary seaworthy lifeboats (Redningsskøytene) and the polar research ship Fram (1892). But he also designed the Léon, a 33 m long brigantine that served in the North and Baltic Seas for decades. Model ships of her are to be found in many maritime museums and probably in many living rooms too. We have changed as little as possible of her original character to meet current requirements/regulations and the quite different intended use. From her genes comes our prototype of a multi-purpose research vessel (LRV), which is the basis for all our marine conservation activities.

The Georg Stage II (1934)

The current Georg Stage is the second to be launched under that name. It was built during five months in 1934 at Frederikshavn Værft og Flydedok and was launched in 1934. It is a Danish iron-hulled, fully rigged, three-masted sailing ship. Over a length of 54 m (177 ft), a width of 8.4 m (28 ft) and draft of 4.2 m (14 ft) the ship spawns 20 sails with a total area of 860 m2 (9,300 sq ft), with the tallest mast extending 31 m (102 ft) above deck height.

Differences to historical designs

The most obvious differences to the historical models concern the main construction material, the auxiliary propulsion, the anchor gear and winch, the navigation equipment as well as the interior of the ship, especially galley, refrigeration and sanitary rooms and areas and facilities that logically did not exist those days – such as the diving base.

The construction method also differs significantly. Historically, caulked planks were built over naturally curved or steam-bent frames. We make the hull, deck, frames and stringers as well as the masts from wood epoxy laminate. This construction method is by far better than the historical one in every respect, be it durability, strength, moldability or material waste. The rigging, on the other hand, will largely correspond to that of the past and, thus, will not least become a popular team-building activity under the guidance of the ship’s crew for the co-creators. The exterior appearance will also be largely unchanged and thus increase the recognisability and the positive image of the ship.

Interior: Practical robust interior, 10-12 Co-Creator-double-cabins with WC and shower, crew-cabins, navigation and sonar room, medical treatment room and pharmacy, diving equipment room with compressor room and gas blending, laboratory (water analysis) fitness room and sauna, galley with cold store, laundry, cargo hold for garbage from the sea, cargo hold for goods, workshops for wood, sails, diving equipment, two deckhouses, watertight compartments.

Diving: Like all our boat and ships, the LRVs will be equipped with a breathing air compressor, O2 booster, gas storage for helium, oxygen and argon to enable research dives to a standard depth of 120m. With regard to our diving gases, we also pay attention to the highest possible sustainability (helium!) and thus when ever possible use high performance closed circuit rebreathers (CCR). In a further stage of expansion, a decompression chamber will be installed between the diving and hospital departments at a later date.

Mission: With her, we will search for dangerous wrecks, identify and decontaminate them, remove ghost nets, plastic and other rubbish from the coasts all year round with a crew of 8-10 and about 20 volunteer members.

As part of field trials with scientific research partners, we will also carry out emission-free transport of goods and passengers (e.g. olive oil from Crete to Trieste and wood back, or island transfers for co-creators).

Vision: We consider our LRV to be the prototype for a series of sailing vessels that we build in our shipyard as powerful tools for ourselves and other marine conservation organisations.

Range of operation: Wreck search, identification and decontamination;

coastal cleanups (beach, coast and seabed down to a depth of over 100 meters);

zero-emissions shipping (e.g. olive oil from Crete to Trieste and lumber back).

Funding: Our LRV is to be financed by our co-creators. Under no circumstances will there be investors with profit expectations! We offer all supporters incomparable experiences on board, voting rights and insights into a transparent use of funds.

Your support is not a one-way street! As an NPO, we can’t offer you interest, capital growth or anything like that, but we can offer you unique benefits on board our LRV and in the Marine Conservation Camp – and of course healthier seas!

Exploration and Oceanography: A Side-Scan Sonar (SSS) provides high resolution sonar images of the sea floor. It is towed to the desired depth and scans the sea floor up to a width of 300 m. The ideal device for wreck search. A Diving robot (ROUV – Remotely Operated Underwater Vehicle) is used for detailed exploration of potential wreck hits. The system delivers HD quality pictures and videos, has a manipulator, a high payload and can do much more (e.g. attach a descent line to a wreck)

Technical equipment: Electric secondary propulsion (possibly hybrid), hydrogenerator, pv-panels, heating (with renewable fuel), hot water by solar thermal collector, biological water treatment plant, movable inner trim ballast.

Interested? Questions?

Let’s chat now on Threema, Whatsapp or Linkedin.

Or simply register with no obligation here and we will send you all the information and documents by email.

Are you interested in working with us?